Lyophilization or Freeze-Drying: The Definitive Guide

Biosimilars and parenteral generally require drying at the stage of final bulk packaging. But traditional drying techniques can’t be used since they require high heat which can denature such products.

So, to overcome this; freeze-drying or Lyophilization method is employed which dry such products using low heat to remove the unnecessary solvents.

Table of Content

Lyophilization Definition

Lyophilization is a simple dehydration technique where;

- The product mixture is frozen first and

- Vacuum is applied to dry the product.

Equipment used to conduct the lyophilization process is called Lyophilizer.

The ice under the vacuum directly changes to vapor without attaining the liquid phase. This condition helps the product to stabilize. It also minimizes the impact of oxidation that may degrade the product quality.

Lyophilization Process

The lyophilization process involves three main sub-steps:

- Freezing – Ice formation

- Primary Drying – Sublimation

- Secondary Drying – Desorption

One of the major advantages of using Lyophilization is that it consumes less heat for drying the product. Also, the harvested powder has enhanced integrity and stability.

However, the major downfall of this process is increased cycle time.

Often, pretreatment operations are conducted before starting the lyophilization process to improve final product quality and yield.

Let us see the most common pretreatment options.

Pre-Treatment Options

Preserving Appearance of the Product

Once the formulated product (e.g., cosmetics) enters into the commercial market, the physical properties become extremely important.

For lower product concentrations, lyophilization may cause even a slight settling of the product in vials or bottles. For such products, third-party agents (also called bulking agents) are added to preserve the overall product appearance.

Stabilization of Reactive Products

In particular, biosimilar products are prone to witness irreversible changes in their molecular structure or degradation during lyophilization.

This happens because lyophilization processes are carried out at much lower temperatures.

To save and stabilize the product from such serious issues, stabilizers (also called lyo-protectants) are introduced during lyophilization.

Moisture is one of the crucial factors contributing to degradation. Hence, along with such stabilizers, framing the moisture requirements is equally important.

Reduced Application of High Vapor Pressure Solvents

High vapor pressure solvents have very low freezing points.

During the freeze-drying step, these solvents will first come off rapidly. Also, for an excessive quantity of the solvent, a product may melt at high pressures in the chamber.

To remove such excessive solvents, pre-treatment involves the application of equipment like Rota-vapors, centrifuges, etc.

When the low temperature of the product is the priority, we can use solvent traps such as liquid nitrogen traps in a vacuum line to remove excessive amounts of solvents.

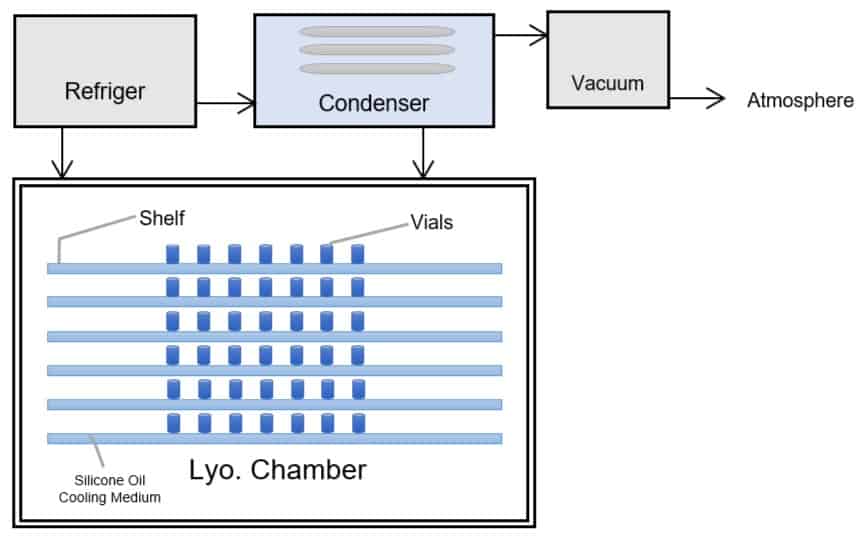

Lyophilizers typically have the following components:

- Shelves

- Trays (required for large volume processing) or Vials

- Condenser

- Heat transfer fluid recirculation pump and its stand-by

- Vacuum Pump

- Hydraulic Cylinders

- Plate Type Heat Exchangers

- Compressors

- Steam supply for sterilization

Background

Product shelf-life is directly related to the amount of moisture present in it. If the product is exposed to excessive water, it may deteriorate later.

Hence, it is important to consider a suitable drying technique.

If the freeze-drying process is not handled efficiently, it may lead to days and weeks to complete. Although, a Quality by Design (QbD) approach will help in effective control of the cycle right from the conceptualization stage.

QbD is a systematic approach to process development with pre-defined objectives that focus on the study of the product, process, and process controls based on statistics, science, and risk.

Some of the important aspects of QbD are Critical Quality Attributes (CQAs), Critical Process Parameters (CPPs), and Critical Material Attributes (CMAs).

As per ICH Q8, Pharmaceutical Development Guidance, fundamental elements of QbD include Design Space and Process Analytical Technology, which were defined in 2004 by the FDA.

These aspects in agreement with ICH (International Conference for Harmonization) have been updated to the QbD approach later in 2009-10. In the design of the Lyophilizer described further, each of the above has a particular significance.

Design Space and Process Analytical Technology (PAT)

Design Space is a multi-dimensional blend of input variables and process parameters shown to provide quality assurance.

Design Space as outlined in ICH Q8, Pharmaceutical Development Guidance

Process Analytical Technology is a risk-based framework which includes a set of scientific tools to support innovation and regulatory implementation strategy to allow the innovation.

Guidance for Industry PAT, FDA

Critical Quality Attributes (CQAs)

These attributes include physical, chemical, or biological characteristics required to ensure the desired product quality.

Assessing the risks in accordance with ICH Q9, these attributes can be derived and defined in a scientifically sound manner. This approach results in robust and effective control strategies.

Examples of Lyophilization CQAs:

- Appearance of the material

- Allied substances

- Moisture Content

Critical Process Parameters (CPPs)

Critical Process Parameters define how the process interacts with the product as it advances.

Examples of Lyophilization CPPs:

- Temperature of Freezing the product

- Primary Drying temperature and pressure (vacuum)

- Secondary Drying temperature and pressure (vacuum)

Critical Material Attributes (CMAs)

In order to manufacture quality products, attributes determine the criticality of the properties of the materials.

Examples of Lyophilization CMAs:

- Heat transfer capability of the shelves

- Product and Eutectic temperature

- Product Morphology

- Conductivity of water vapors

- For vials, heat transfer coefficient of the glass and

- For trays, heat transfer coefficient of SS316L

Lyophilization Process Steps

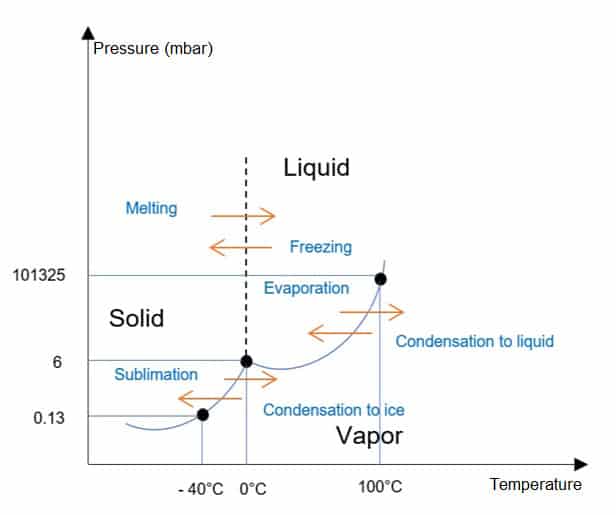

Here is a description of each phase of lyophilization. Below is a phase diagram of the lyophilization process.

(Left to Right)

1st Black Spot – Freezing Point

2nd – Triple Point, and

3rd – Critical Point

There are two types of moisture.

- Free Moisture (Unbound Moisture)

- Bound Moisture

Free moisture freezes at lower temperatures and hence is easy to separate. The opposite is the case for bound moisture.

A Typical Lyophilizer Diagram

The most suitable heat transfer fluid is generally Silicone Oil, which has a less freezing point than the product. Such heat transferring fluids spread inside the shelves with the help of a circulation pump installed outside the controlled area.

Shelves contain high-grade material with enhanced thermal conductivity for better heat transfer. Vials typically have glass as their MOC whereas trays have SS316L.

Instrumentation and process control may include:

- Compound Pressure and Temperature Transmitter

- PLC, HMI, or dedicated SCADA System

- Chart recorders

Manual intervention is limited to the initial stage of a cycle when an automated system is used. After loading the pre-saved recipe parameters with a unique batch ID, the operator inserts the temperature probes into the vials or trays.

Key parameters of the recipe may include:

- Shelf Temperature

- Product Temperature

- Chamber Pressure

- Secondary Drying – Shelf Temperature

- Secondary Drying times, etc.

Obviously, these recipes should comply with process validation requirements. Sometimes these recipe parameters may change from time to time based on the process dynamics and hence may require time to time verification.

Before initiating the Lyophilization process, Cleaning in Place, Pressure Leak Test, and Sterilization in Place cycles are carried out to ensure the system is ready to process.

Step 1: Freezing Phase

We consider this stage to be the most critical in terms of productivity. The product is frozen below the eutectic point.

A Eutectic Point is the point in the phase diagram where all three phases co-exist and the temperature and composition of the liquid phase cannot be altered without disappearing one of the phases. Any product will experience the heat of fusion at lowered temperatures.

The liquid becomes solid in two different ways.

- Liquid to solid crystals at a non-steady rate (Crystallization)

- Liquid to solid (non-crystal) at a steady rate (Vitrification OR Glass Transition)

Uniform temperature distribution across the complete product setup is a crucial aspect of lyophilization. Hence, it is important to properly distribute the temperature probes across the shelves.

Temperature control altogether depends on the behavior of the water. The challenge is to maintain the super-cooled state of the water. A slow rate of freezing creates large-sized ice crystals. This creates an effective lyophilization process. The slow rate may lead to void spaces allowing water to escape during drying. The rapid rate of freezing creates small-sized ice crystals, which makes the lyophilization process cumbersome.

Once the temperature of the solution is reduced continuously under atmospheric pressure and below freezing temperature, the solution enters a super-cooled state.

A proper thermal analysis of the drying chamber will help in mapping the way the freeze-drying would proceed, including time vs. temperature curve and proper heat studies.

Step 2: Primary Drying Phase

This is the second stage of the lyophilization process where sublimation starts and is an initial drying phase. First, the vacuum pump removes non-condensable vapors from the lyophilizer.

The ice formed during the previous stage gets removed here by directly sublimating to vapor under a vacuum. This easy removal is considered unbound removal of the solvent or the water. Hence it is called Primary Drying Phase.

A key driving force for sublimation during primary drying is the pressure differential between product and condenser. As the temperature of the solvent decreases, the pressure also decreases.

Therefore, the temperature of the condenser must be lower than the temperature of the product which will drive the vapors from the chamber towards the condenser.

In sublimation, this ice (solid phase) directly transforms to vapors without attaining the liquid phase. Vapors are then collected and condensed into liquid in a pre-cooled condenser in the service area. When performed continuously, this process results in a dried product.

Manufacturers generally measure vacuum either in mbar or in mtorr (Torricelli).

During drying, both heat and mass transfer happen in parallel. Therefore, the design of the chamber should promote the flow of the vapors towards the condenser.

In the case of vials, the position of vials plays an important role in the design space. Chamber walls impose radiation mode of heat transfer. When vials are placed centrally, radiation does not influence them. But when placed off-center, radiation does influence the vials.

The rate of sublimation plays an important role in condenser sizing and heat load calculations. A higher rate of sublimation may cause less efficient condensation.

Finally, the ice formed inside the condenser may disturb its pressure. This causes the product to melt inside the chamber. This critical temperature is called glass transition temperature or collapse temperature.

Step 3: Secondary Drying Phase

This is the bound moisture or solvent removal stage, where residual water content gets converted to vapor and removed from the vials or trays. This water has lower vapor pressure than that of unbound property. Products in secondary drying often appear dry, but they contain unfrozen water molecules in frozen water, hence not completely dry.

During this stage, temperature elevates, and pressure reduces without affecting the quality of the product and breaks down the molecular bonding between the product and excess bound moisture. This process is called desorption.

Finally, the pressure slightly elevates to the atmospheric pressure and thus the process completes upon following conditions.

- Product Temperature = Shelf Temperature

- Meaning: Heat transfer has reached its equilibrium

- Significant decrease in vapor molecules

- Return of temperature to its default value for condenser

The system is then brought back to atmospheric pressure. The trays are unloaded and the freeze-dried products are stored as soon as possible to avoid moisture absorbance.

Freeze dryers for parenteral, biosimilars, etc. are kept under Laminar Air Flow Units (Class A) to maintain the aseptic conditions. The surrounding area is supposed to include a controlled atmosphere of Class B.

Heat Transfer Modes During Lyophilization Process

Considering the lyophilization of vials, three different modes of heat transfer occur during the Freeze-Drying process.

- Conduction (Solid to Solid, Solid to Liquid)

- Convection (Liquid to Liquid)

- Radiation (Thermal Energy Transmission by Electromagnetic Waves)

Conduction

Vials are solid glass containers containing material inside them. Therefore, vials and their material come in direct thermal contact with the shelves on which they are placed. Heat transfer starts from shelves, then to vials, and then to subsequent material under drying.

Convection

This occurs due to bulk fluid motion. Circulating pressure enhances the rate of convective heat transfer, which speeds up the drying process.

Radiation

Microwaves or thermal radiation occur inside the lyophilization chamber because of the heat emitted by the open space of the shelves. The vacuum also plays an important role in carrying electromagnetic waves.

Equipment Breakdown and Maintenance

A risk assessment would help in identifying potential risks and associated corrective actions. An FMEA (Failure Mode Effect Analysis) would help in case of a potential malfunction.

Suitable in-process checks help in identifying chamber leakages such as oil leakage and associated impact on the product.

To sum up, the following things must be considered for troubleshooting the breakdown or maintenance-related activities.

- Risk Assessment (FMEA)

- Multiple In-Process checks

- Periodic Preventive Maintenance and Logs

- Equipment Discrepancy Records

- Change Control Log

- Power failure behavior

- Regular defrosting of the condenser to ensure stuck-up ice removal

Validation Approach

As mentioned earlier, the eutectic point has its own importance while validating the lyophilization cycle. Dryer manufacturers may find it difficult to derive the eutectic points of specific products that lead to cycle failures.

The rate of freezing and temperature ramp-up also plays an important role while developing lyophilization cycles on commercial levels.

For multi-product facilities, a single recipe may not provide a solution for successful lyophilization process cycles for different products. Hence, every product may have its own cycle parameters to consider while developing a recipe.

As per the FDA recommendation, manufacturers are advised to conduct frequent discussions on Interim validation reports for troubleshooting of the concerned parameters and hassle-free investigations.

Drug manufacturers must consider these concerns during the course of process validation.

Shelf vs. Vial Temperature: A Commonly Overlooked Gap

One of the most frequent and underestimated challenges in lyophilization is proving that shelf temperature (T_shelf) directly correlates with vial product temperature (T_product).

In an actual FDA audit during a lyophilizer SAT at a major pharma facility, an inspector asked a simple but critical question:

“How do you prove that a ±0.5°C deviation on shelf temperature gives you the same impact on product temperature in the vial?”

This wasn’t just theory. It was about heat transfer modeling and thermal uniformity validation; two elements many firms overlook or fail to document properly.

Key FDA Audit Findings Around This Gap

Here are common 483 observations:

❌ Lack of direct measurement of product temperature during primary drying

❌ Missing or insufficient edge vial temperature mapping

❌ Overreliance on shelf temp control as a surrogate without correlation data

❌ No documentation of vial heat transfer studies

How to Defend With Science, Not Smart Answers

You need more than calibration certificates and setpoint logs.

Here’s what top-tier responses look like:

✅ Use thermocouples in multiple vial positions (center + edges) to validate product temp range

✅ Perform heat transfer modeling (radiation, conduction), not just convection assumptions

✅ Use infrared (IR) thermal mapping where feasible

✅ Show correlation studies over multiple loads and product types

✅ Include edge vial data in every performance qualification (PQ) and justify any exclusions

✅ Partner with academic institutions (e.g., Univ. of Colorado) for radiation modeling if needed

When you can quantify heat transfer pathways, simulate edge effects, and show repeatable drying behavior, you’re not just defending your cycle – you’re mastering it.

Sterilization of Lyophilizer

To demonstrate the validated state, the dryer design must promote the QbD aspect. This may include inaccessible locations such as nitrogen lines or process airlines. Hence, steam may require a simple design of the equipment with fewer bends and zero dead legs.

Ethylene Oxide gas may be considered for sterilization in place of steam but with some limitations, because humidification may be required for uniform moisture distribution, adding more challenges. Being a gas, ethylene oxide may stagnate in nitrogen and process piping. This imposes a risk in ensuring the complete removal of the gas.

Hence, clean steam is practiced for sterilization with the simpler piping design of the equipment. The setup required to conduct steam sterilization follows the same as that of an autoclave. Apart from regular temperature probes, dedicated ones require installation in the chamber and low drain points to control hot and cold spots. Finally, the sterilization cycle is developed and the effectiveness of the steam sterilization is evaluated.

Once the sterilization cycle is complete, performing proper air flushing ensures the system gets dry. This whole thing may be achieved through the application of the automated sequence for steam sterilization. Sterilization frequency is generally kept after the completion of each batch.

Regularly testing the filter integrity is necessary for steam supply filters if applicable. Once the sterilization ends, positive pressure is maintained inside the system to avoid entrance of the contaminated air, and the system attains a vacuum as per the preset value.

Lyophilization: FAQ

Why is lyophilization important?

Drying without heating, simple handling of aseptic requirements, and improved product stability are key interests of using lyophilization. Apart from that, products that are heat sensitive and can sustain only in low temperatures, lyophilization comes out as a reliable and proven technique to get things done. This process also has some disadvantages such as being expensive, tricky, and of increased cycle times.

Does lyophilization kill bacteria?

Mostly No. It only de-activates them because of lowered temperatures. Once the temperature rises, they re-activate again. In exception, very few of them may get killed based on their family and origin. Low temperatures affect their cell wall structure even when it bursts.

Is lyophilization the same as freeze drying?

Yes. These are the same terms used interchangeably as per relevance to the specific applications. Lyophilization is derived from the word lyophilic, meaning a colloid of the particles having a strong affinity for the liquid in which it gets dispersed.

Why is lyophilization of parenteral drugs required?

In simple words, to increase the shelf life of the pharmaceutical product. Also, lyophilization is well known for keeping the product valued and within quality limits.

What is the principle of lyophilization?

Lyophilization is based on the principle of sublimation. Sublimation is the change of phase from solid to a gas without attaining a liquid state. This sublimation is the effect of the applied vacuum on the system. Ice formation, followed by reduced pressure sequentially, triggers sublimation.

How long does it take to Lyophilize?

It depends on the type of equipment, process, product, and application. It will take anywhere from 24 to 72 hrs. of cycle time to complete the lyophilization process. Automation and system complexity may increase or decrease cycle time.

Will you please write an article about ultra sonicator?

Thanks, Yogita. I would have loved to but honestly, I do not have sound know-how of it.

Very Nice dude!

One thing need to add in this the pictorial representation of heat & mass transfer in Chamber.

Thanks, Ravindra for your feedback. Will definitely look into the revision as possible.

Very informative!

Thank You!

Please write article about Preparative HPLC

Hi Vishal!

Here it is: https://pharmagxp.com/process-engineering/preparative-hplc-system-rphplc/

Very nice, suitable and essential articles for Healthcare professionals..!!

Hi Dinesh! Glad that you find these valuable. I wish you all the best and stay tuned.

Very Good Article !

Thanks!